Retrofitting & Upgradation

Retrofitting Up-gradation Services

Octagon provides the retrofitting & up-gradation services to old metrology equipment of any make. In this service we upgrade machine with the old technology by latest technology featuring interface of computerized software.

Octagon offers retrofitting and up-gradation services for different old length and form measuring machines of various makes. Following various types of old measuring machines are up-graded with the integration of latest technology.

- Universal length measuring machines of various models and makes

- Roundness and cylindricity testing machines of various models and makes

- Gauge blocks comparators of various models and make

- Camshaft measuring machines

1

The technology up-gradation of Old Optical / Electronic Length Measuring Machines are carried out by installing high precision electronic encoder systems. Further to this Octagon ULM Inspect gauge management software is interfaced for online, data acquisition, processing of measurement data and report generation. Online thermal error compensation facility is also available request.

This up-gradation enables to reduce operating time, measurement skill and helps to achieve the original manufacturer accuracies.

2

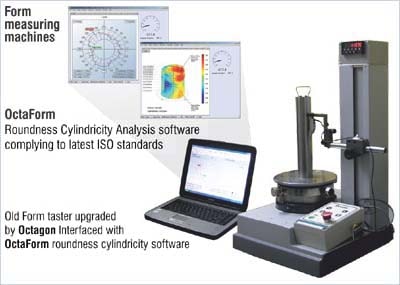

The technological up-gradation of old Form testers (roundness and roundness-cylindricity measuring machines) are carried out by interfacing Octagon OctaForm windows based online data acquisition and analysis software ,which also provides graphical report. The up-gradation kit consists the electronics interface hardware, power supply with motion controller and measuring sensor (optional)

Octagon also provides up-gradation of roundness testers to convert it in to roundness–cylindricity measuring machines . This option of up-gradation is available on demand in which simple z axis column is replaced with precision motorized Z axis column assembly . The graphical analysis report helps to easy interpretation of results.

3

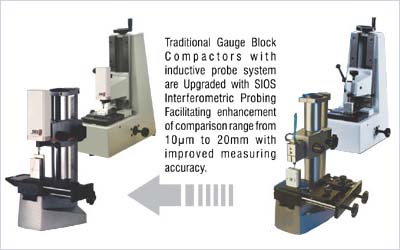

The technological of old Gauge Block Comparators are carried out by either replacing old inductive probes with latest interferometric / optical probes and interfacing windows based software or just by interfacing with software with the old readout system. Octagon Gauge block measuring software is windows based program for online data acquisition and analysis of parallel gauge blocks , which also has added features for online thermal error compensation. Software guides operator step by step thought the measurement cycle.

The up-gradation kit consists of new measuring probes (If required) , electronic interface hardware and the Octagon Gauge Block measurement software.

4

Technological up-gradations of old optical CAM testers are carried out by installing high precision angle & linear encoders to enhance the accuracies.

1. Software for online data acquisition of Angle Vs lift

2. Software for online data acquisition of Angle Vs Lift and further analysis of measured data with latest mathematical algorithms for corrections of part alignments ( base circle run-out corrections, correction across journal axis) which gives you a through analysis report of the part.